- 2025-02-27 16:21 1305

- 产品价格:面议

- 发货地址:山东潍坊坊子区 包装说明:不限

- 产品数量:9999.00 个产品规格:不限

- 信息编号:192606389公司编号:13827888

- 段经理 销售经理 微信 13006562205

- 进入店铺 在线留言 QQ咨询 在线询价

惠州消火供货商

- 相关产品:

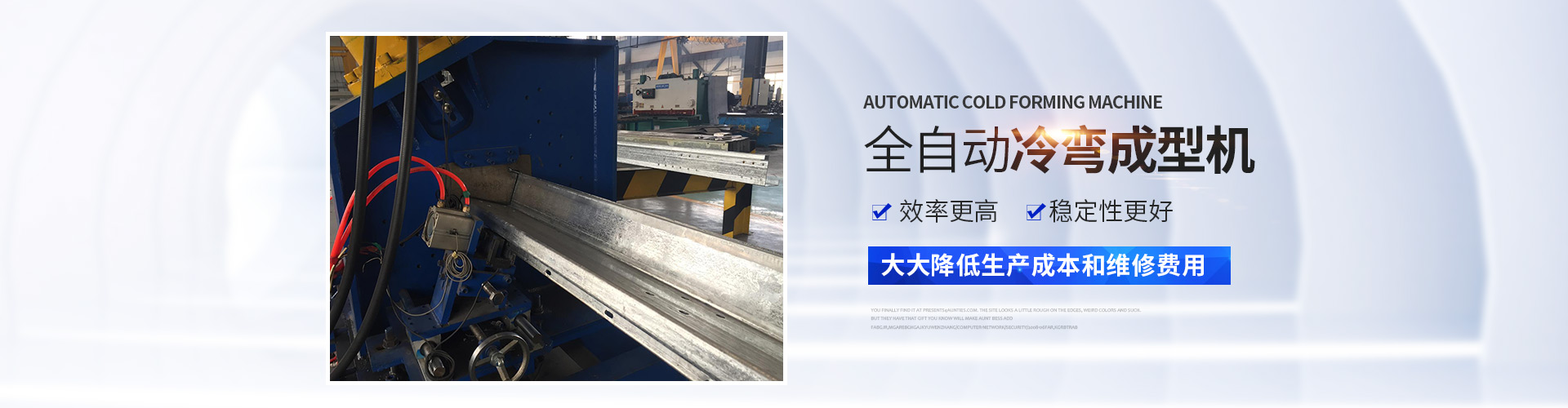

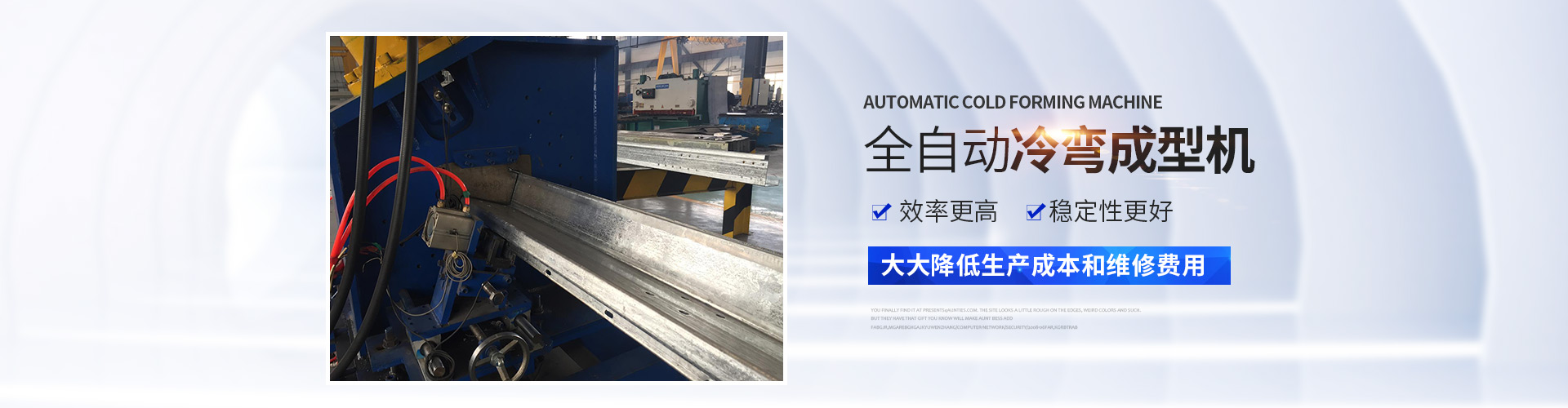

潍坊奥腾冷弯机械有限公司制造的全自动消火箱箱体冷弯成型设备,对很多消防器材厂来说,无疑是福音,设备改变了传统的加工模式,使得效率呈几何倍数翻翻,但我们不会就此停止,我们将更加努力的研发创新,期待未来的我们。更为行业创造更多的设备!

愿我们的客户成为的企业!

望的企业成为我们的客户!

For ny firefighting equipment factories, the autotic cold-forming equipment of fire box de by Weifang OTeng Cold bending chinery Co., Ltd. is undoubtedly a good news. The equipment has changed the traditional processing mode and de the efficiency turn over in geometric multiples. But we will not stop, we will work harder on R & D innovation, looking forward to the future of us. More industry to create more quality equipment!

Wish our customers become enterprises!

The enterprise of hope becomes our customer!

为创造,提高企业度,树立企业形象,我们本着“一切追求高质量,用户满意为宗旨”的精神,以“的价格、周到的服务、可靠的产品质量”的原则向您郑重承诺:

因使用原因造成设备损坏等问题的善后费用(服务人员往返差旅费等)由使用方承担。

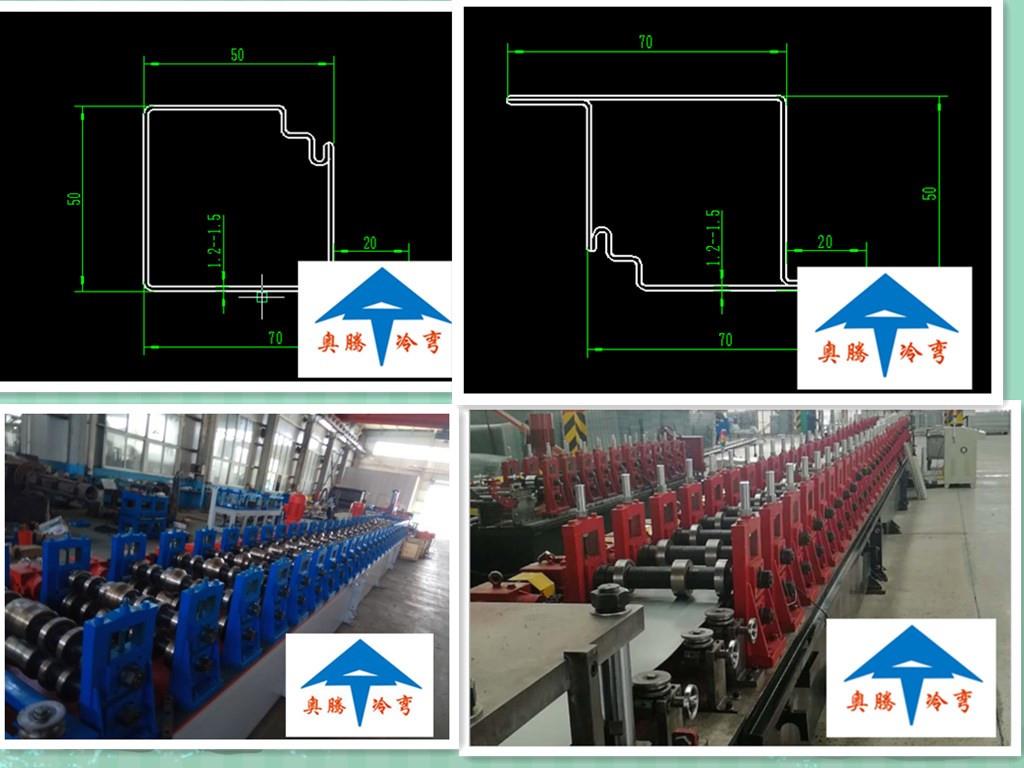

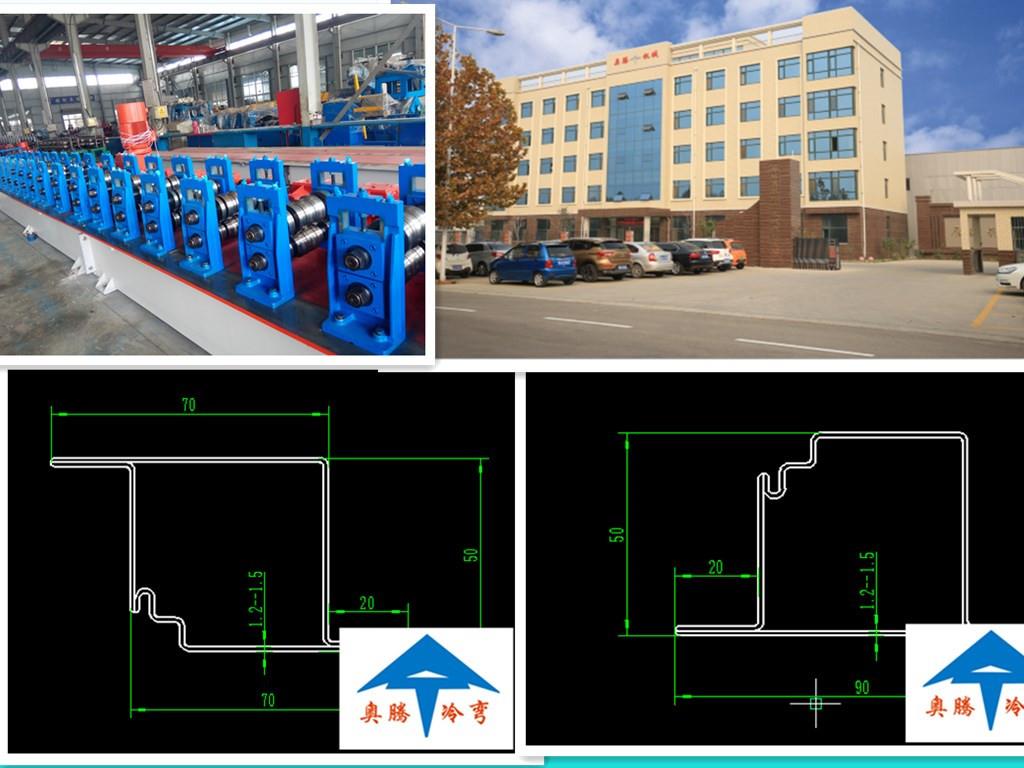

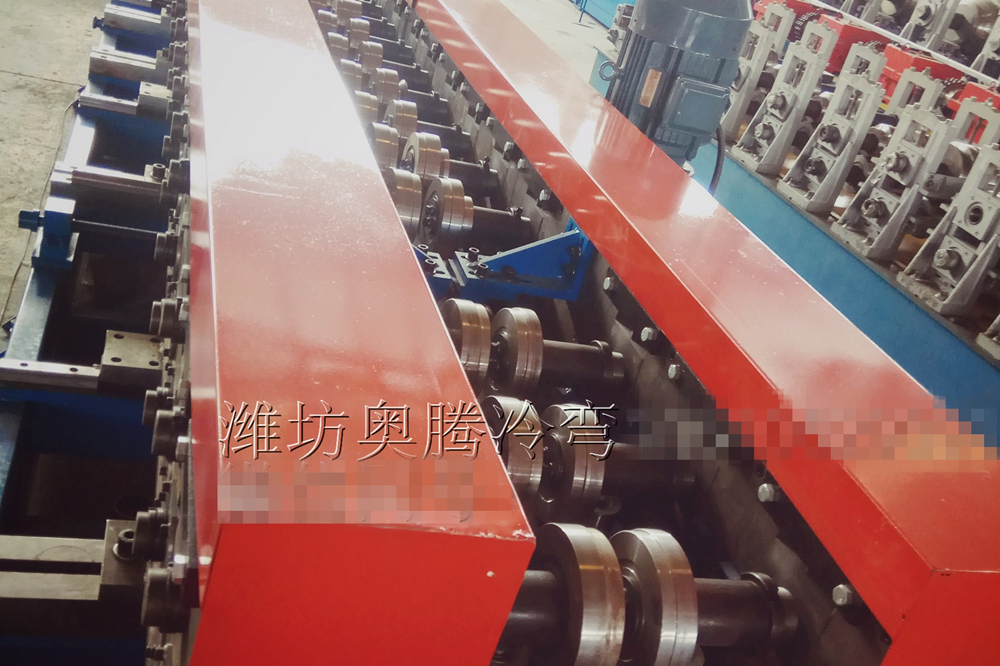

消火栓箱箱体设备工艺流程:开卷机-校平机-伺服送料、冲孔-冷弯成型-自动折弯-切断

材料材质:Q235 、不锈钢

钢带厚度:0.8~1.2 mm

钢带宽度: 根据消防箱大小规格

生产速度:约100个箱体//每小时

总电机功率:约25kw

液压站功率:5.5kw

切断方式:液压切断

电气控制:PLC

驱动电机:变频电机驱动

开卷机称重:4吨

气源:0.6MPa

电压参数:380V,50Hz, 3相

切断尺寸公差:≤ ±0.5mm

切断模具材质: Cr12MoV

轧辊材质:Cr12 淬火HRC58--62°

主轴直径:Ф65mm或Ф75mm

Fire hydrant box equipment process: uncoiling chine-leveling chine-servo feed, punching-cold forming-autotic bending-cutting

terial terial: Q235, stainless steel

Steel strip thickness: 0.8 mm 1.2 mm

Strip width: according to fire box size specification

Speed of production: about 100 cases per hour

Total motor power: about 25kw

Hydraulic station power: 5.5 kw

Cut off mode: hydraulic cutting

Electrical control: PLC

Drive motor: frequency conversion motor drive

ximum weight of unwinding chine: 4 tons

Gas source: 0.6MPa

Voltage parameter: 380V, 50Hz, 3 phase

Cut off dimensional tolerance: ≤ ±0.5mm

Cutting mould terial: Cr12MoV

Roll terial: 1: Cr12 quenching HRC58-62 °

Spindle diameter: 65mm or 75mm