- 604

- 产品价格:699.00 元/套 起

- 发货地址:山东潍坊潍城区 包装说明:不限

- 产品数量:9999.00 套产品规格:不限

- 信息编号:145466655公司编号:14582956

- 王振友 经理 微信 18053628930

- 进入店铺 在线留言 QQ咨询 在线询价

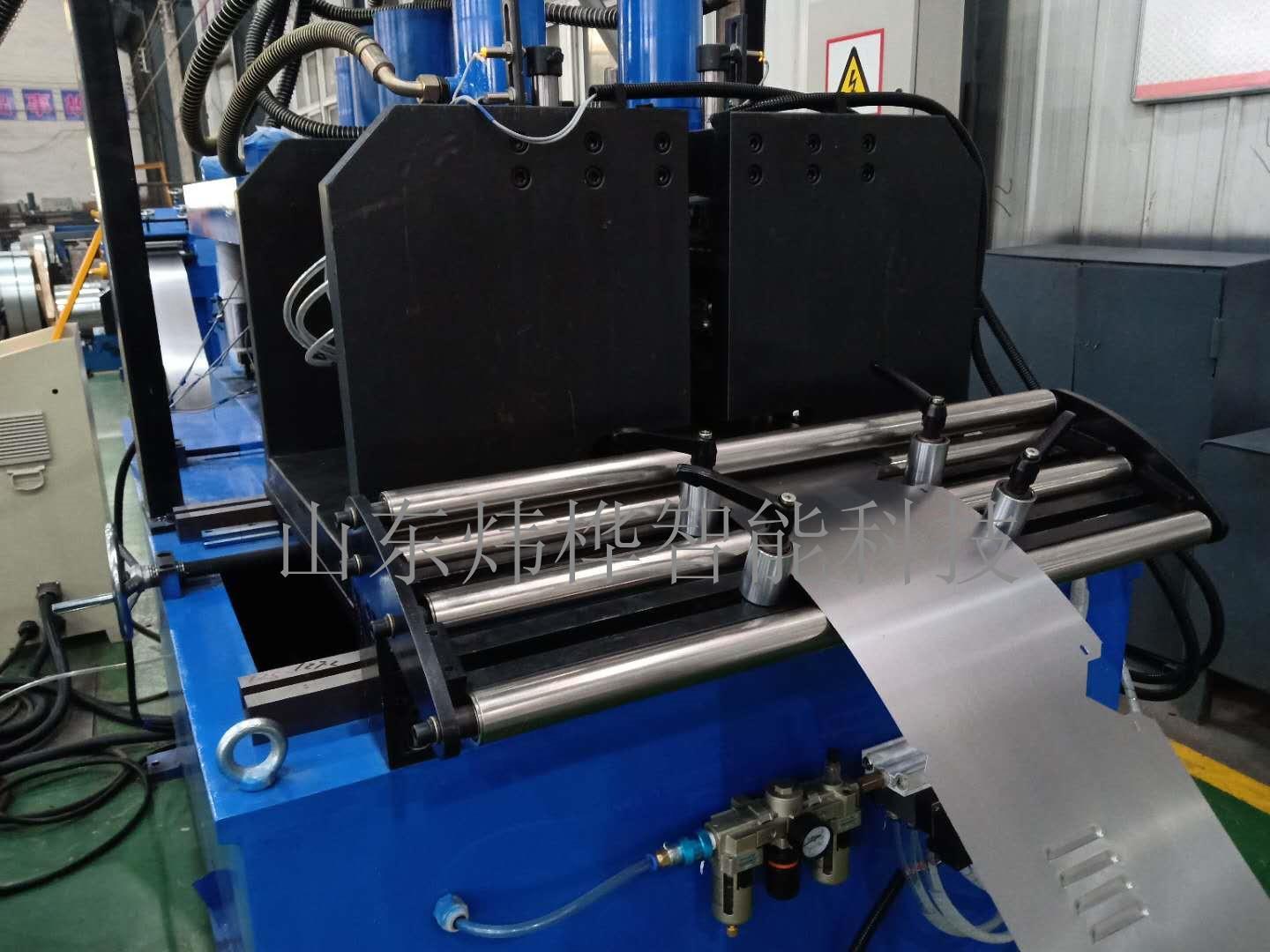

消防箱箱体生产线出租 自动成型

- 相关产品:

设备结构及系统配置:

Equipment structure and system configuration:

概述:该生产线主要由放料机、调平机、冲孔切断机、输送台、成型主机、液压折边机、成品托料装置、液压系统、电气控制部分及安全防护部分组成。

Overview: The production line is mainly composed of feeder, leveler, punch cutter, conveyor, forming machine, hydraulic folding machine, finished product supporting device, hydraulic system, electrical control part and safety protection part.

1.放料机:用于存入放卷料并给成形部分提供板料,5吨电动放料机液压张紧。

1. Feeder: Used for storing coil and supplying sheet metal to forming part, hydraulic tension of 5 ton electric feeder.

2.整平机:9辊精密整平(上4下5),2.2KW电动送料,用于卷料平直并消除材料应力。

2. Leveling machine: 9 rolls precision leveling (top 4 down 5), 2.2KW electric feeding, used for coiling straightening and eliminating material stress.

3.伺服送料机:含2KW伺服系统,精密送料器,冲孔装置(模具)和切断装置。

3. Servo feeder: including 2KW servo system, precision feeder, punching device (die) and cutting device.

2.成型主机:此生产线的主机机座采用100*100*3MM方钢焊接,机架采用整体式固定牌坊,侧板采用30mm钢板,支承部分均采用优质闽台轴承,进料采用滚轮式,出料采用扭动上下调节,主机钢性好,且结构稳定。

2. Forming machine: The main frame of this production line is welded with 100*100*3MM square steel, the frame is fixed with integral archway, the side plate is made of 30mm steel plate, the supporting part is made of high-quality Taiwanese bearings, the feeding part is rolled, the feeding part is adjusted up and down by torsion, and the main frame is good in steel and stable in structure.

成型参数

Molding parameters

a、 成型组数:16组辊轮成型

A. Forming group: 16 sets of rollers forming

b、 主轴规格:?48mm 45#钢材料调质处理

B. Spindle specification:? 48mm 45# steel material tempering treatment

c、 辊轮材质:Gr12模具钢热处理

C. Roller Material: Heat Treatment of Gr12 Die Steel

d、 整体式牌坊:由25mm钢板精加工而成,孔距误差小于0.1mm

D. Integral archway: made of 25 mm steel plate, with hole spacing error less than 0.1 mm

e、 底板厚度:20mm

E. Floor thickness: 20mm

4、成型能力

4. Forming ability

a. 带卷外径: Φ1250mm(Max.)

A. Outer diameter of tape coil: 1250mm (Max.)

b. 材料成型厚度:0.4-1.0mm

B. Material forming thickness: 0.4-1.0mm

c. 产品宽度100mm-400mm可调

C. The width of the product is adjustable from 100mm to 400mm.

5、成型机组速度参数

5. Speed parameters of forming unit

a. 线速度 0-13m/min

A. Linear velocity 0-13m/min

b. 加速时间 <30秒

B. Acceleration time less than 30 seconds

炜桦冷弯自04年成立以来,一直致力于企业的智能化升级改造,现已是业内****企业,其优质高效的消防箱成型设备现已销往了整个全国市场,为客户满意度很高的产品,只要客户按时按量保养维护,操作方法按照开始培训的操作,基本不会出现差误,若出现设备问题,炜桦会安排专业售后人员到达客户现场进行维修或升级服务,一直都以客户满意为宗旨,快速、果断、周到,欢迎各位老板入企研讨。

生产线操作:威纶触控屏

控制方式:PLC控制器(设置做种安全防护,提升生产安全性,降低电子元件的故障率)

正常生产是功率:32kw左右

切断部分:液压模具切断

冲压、切断模具材质:铬12钼钒

轧辊用料:铬12 淬火HRC58°-62°

液压站:电机采用西门子电机(更耐用,减少故障出现)

原材料规格:客户定制

生产占地:23000*2000*1800(长*宽*高)mm;大约

公差范围(切断尺寸):≤ ±0.5mm(长≤3000mm)

新型箱体产品特点:

Features of new box products:

我公司研发的配电箱加工生产线为配电箱一次成型设备。该设备打破了传统生产方式,对多个工艺步骤进行了优化改进,使配电箱钣金加工的综合生产效率提高3倍以上,部分环节工序可提高效率10倍以上!日生产箱体1000只,在人员和场地减少的情况下,实现实际生产效率增加数倍;伺服控制和高精度冷弯成型等多项国家技术,确保了箱体的钣金制造精度,实现箱体机械强度更高。

The distribution box processing line developed by our company is the primary forming equipment of the distribution box. The equipment breaks the traditional production mode, optimizes and improves several process steps, and improves the overall production efficiency of sheet metal processing of distribution box by more than three times, and some process steps can improve efficiency by more than 10 times. The daily production of 1000 boxes, in the case of reduced personnel and site, to achieve a multiplier of the actual production efficiency; servo control and high-precision cold bending forming and other national technologies, to ensure the accuracy of the box sheet metal manufacturing, to achieve higher mechanical strength of the box.

该机组设备占地约50平方米,设备组成主要包括:放料装置、校平装置、自动送料装置、连续冲孔装置、高精度冷弯成型主机、定尺切断装置、自动折框装置、电气控制系统等部件组成;主要功能:自动去角、伺服自动冲孔、自动下料、自动成型、自动折框等。

The unit covers an area of about 50 square meters, and its equipment composition mainly includes: discharging device, leveling device, automatic feeding device, continuous punching device, high precision cold bending forming machine, fixed length cutting device, automatic folding frame device, electrical control system and other components; its main functions are automatic angle removal, Servo Automatic punching, automatic blanking, automatic forming, automatic folding frame, etc.

生产线主要技术参数:

Main technical parameters of production line:

材料规格:Q235冷轧带钢,镀锌带钢

Material Specification: Q235 Cold Rolled Strip, Galvanized Strip

材料厚度:0.6→1.2mm(可定制)

Material thickness: 0.6 1.2mm (customizable)

生产速度:2只/分钟

Production speed: 2 per minute

生产规格:箱体大小:250*300--800*1000;(可定制)

Production Specification: Box Size: 250*300-800*1000; (Customizable)

箱子深度:160/180/200/250(可定制)

Box depth: 160/180/200/250 (customizable)

电压参数:380V/415V,50Hz, 3相

Voltage parameters: 380V/415V, 50Hz, 3-phase

气源:0.5m3/Min;压力为0.7MPa

Gas source: 0.5m3/Min; pressure: 0.7MPa

液压油型号:46#液压油

Hydraulic Oil Type: 46 # Hydraulic Oil

齿轮油型号:18#齿轮油

Gear Oil Type: 18 # Gear Oil

轧辊材质:Cr12数控加工 ;淬火处理硬度HRC58°-60°

Roll material: Cr12 numerical control processing; hardness of quenching treatment HRC58 - 60.

驱动电机:变频电机驱动

Driving motor: variable frequency motor drive

总电机功率:25kw

Total motor power: 25 kW

切断模具材质: Cr12MoV

Cutting Die Material: Cr12MoV

传动模式:齿轮箱

Drive mode: gearbox

切断方式:液压切断

Cut-off mode: hydraulic cut-off

切断尺寸公差:≤ ±0.5mm(长≤1000mm)

Cut-off dimension tolerance: <0.5mm (length <1000mm)

操作系统:触摸屏人机界面操控

Operating System: Man-machine Interface Control of Touch Screen

电气控制:三菱PLC程序控制

Electrical control: Mitsubishi PLC program control

占地空间: 20*2*3米(长×宽×高)

Coverage space: 20*2*3 m (length width height)

电器柜成型机,配电箱外框冲孔折弯一次成型设备“炜桦冷弯”我们更专业

Electrical cabinet forming machine, one-time forming equipment for punching and bending the outer frame of distribution box "cold bending of birch" we are more professional

Equipment structure and system configuration:

概述:该生产线主要由放料机、调平机、冲孔切断机、输送台、成型主机、液压折边机、成品托料装置、液压系统、电气控制部分及安全防护部分组成。

Overview: The production line is mainly composed of feeder, leveler, punch cutter, conveyor, forming machine, hydraulic folding machine, finished product supporting device, hydraulic system, electrical control part and safety protection part.

1.放料机:用于存入放卷料并给成形部分提供板料,5吨电动放料机液压张紧。

1. Feeder: Used for storing coil and supplying sheet metal to forming part, hydraulic tension of 5 ton electric feeder.

2.整平机:9辊精密整平(上4下5),2.2KW电动送料,用于卷料平直并消除材料应力。

2. Leveling machine: 9 rolls precision leveling (top 4 down 5), 2.2KW electric feeding, used for coiling straightening and eliminating material stress.

3.伺服送料机:含2KW伺服系统,精密送料器,冲孔装置(模具)和切断装置。

3. Servo feeder: including 2KW servo system, precision feeder, punching device (die) and cutting device.

2.成型主机:此生产线的主机机座采用100*100*3MM方钢焊接,机架采用整体式固定牌坊,侧板采用30mm钢板,支承部分均采用优质闽台轴承,进料采用滚轮式,出料采用扭动上下调节,主机钢性好,且结构稳定。

2. Forming machine: The main frame of this production line is welded with 100*100*3MM square steel, the frame is fixed with integral archway, the side plate is made of 30mm steel plate, the supporting part is made of high-quality Taiwanese bearings, the feeding part is rolled, the feeding part is adjusted up and down by torsion, and the main frame is good in steel and stable in structure.

成型参数

Molding parameters

a、 成型组数:16组辊轮成型

A. Forming group: 16 sets of rollers forming

b、 主轴规格:?48mm 45#钢材料调质处理

B. Spindle specification:? 48mm 45# steel material tempering treatment

c、 辊轮材质:Gr12模具钢热处理

C. Roller Material: Heat Treatment of Gr12 Die Steel

d、 整体式牌坊:由25mm钢板精加工而成,孔距误差小于0.1mm

D. Integral archway: made of 25 mm steel plate, with hole spacing error less than 0.1 mm

e、 底板厚度:20mm

E. Floor thickness: 20mm

4、成型能力

4. Forming ability

a. 带卷外径: Φ1250mm(Max.)

A. Outer diameter of tape coil: 1250mm (Max.)

b. 材料成型厚度:0.4-1.0mm

B. Material forming thickness: 0.4-1.0mm

c. 产品宽度100mm-400mm可调

C. The width of the product is adjustable from 100mm to 400mm.

5、成型机组速度参数

5. Speed parameters of forming unit

a. 线速度 0-13m/min

A. Linear velocity 0-13m/min

b. 加速时间 <30秒

B. Acceleration time less than 30 seconds

炜桦冷弯自04年成立以来,一直致力于企业的智能化升级改造,现已是业内****企业,其优质高效的消防箱成型设备现已销往了整个全国市场,为客户满意度很高的产品,只要客户按时按量保养维护,操作方法按照开始培训的操作,基本不会出现差误,若出现设备问题,炜桦会安排专业售后人员到达客户现场进行维修或升级服务,一直都以客户满意为宗旨,快速、果断、周到,欢迎各位老板入企研讨。

生产线操作:威纶触控屏

控制方式:PLC控制器(设置做种安全防护,提升生产安全性,降低电子元件的故障率)

正常生产是功率:32kw左右

切断部分:液压模具切断

冲压、切断模具材质:铬12钼钒

轧辊用料:铬12 淬火HRC58°-62°

液压站:电机采用西门子电机(更耐用,减少故障出现)

原材料规格:客户定制

生产占地:23000*2000*1800(长*宽*高)mm;大约

公差范围(切断尺寸):≤ ±0.5mm(长≤3000mm)

新型箱体产品特点:

Features of new box products:

我公司研发的配电箱加工生产线为配电箱一次成型设备。该设备打破了传统生产方式,对多个工艺步骤进行了优化改进,使配电箱钣金加工的综合生产效率提高3倍以上,部分环节工序可提高效率10倍以上!日生产箱体1000只,在人员和场地减少的情况下,实现实际生产效率增加数倍;伺服控制和高精度冷弯成型等多项国家技术,确保了箱体的钣金制造精度,实现箱体机械强度更高。

The distribution box processing line developed by our company is the primary forming equipment of the distribution box. The equipment breaks the traditional production mode, optimizes and improves several process steps, and improves the overall production efficiency of sheet metal processing of distribution box by more than three times, and some process steps can improve efficiency by more than 10 times. The daily production of 1000 boxes, in the case of reduced personnel and site, to achieve a multiplier of the actual production efficiency; servo control and high-precision cold bending forming and other national technologies, to ensure the accuracy of the box sheet metal manufacturing, to achieve higher mechanical strength of the box.

该机组设备占地约50平方米,设备组成主要包括:放料装置、校平装置、自动送料装置、连续冲孔装置、高精度冷弯成型主机、定尺切断装置、自动折框装置、电气控制系统等部件组成;主要功能:自动去角、伺服自动冲孔、自动下料、自动成型、自动折框等。

The unit covers an area of about 50 square meters, and its equipment composition mainly includes: discharging device, leveling device, automatic feeding device, continuous punching device, high precision cold bending forming machine, fixed length cutting device, automatic folding frame device, electrical control system and other components; its main functions are automatic angle removal, Servo Automatic punching, automatic blanking, automatic forming, automatic folding frame, etc.

生产线主要技术参数:

Main technical parameters of production line:

材料规格:Q235冷轧带钢,镀锌带钢

Material Specification: Q235 Cold Rolled Strip, Galvanized Strip

材料厚度:0.6→1.2mm(可定制)

Material thickness: 0.6 1.2mm (customizable)

生产速度:2只/分钟

Production speed: 2 per minute

生产规格:箱体大小:250*300--800*1000;(可定制)

Production Specification: Box Size: 250*300-800*1000; (Customizable)

箱子深度:160/180/200/250(可定制)

Box depth: 160/180/200/250 (customizable)

电压参数:380V/415V,50Hz, 3相

Voltage parameters: 380V/415V, 50Hz, 3-phase

气源:0.5m3/Min;压力为0.7MPa

Gas source: 0.5m3/Min; pressure: 0.7MPa

液压油型号:46#液压油

Hydraulic Oil Type: 46 # Hydraulic Oil

齿轮油型号:18#齿轮油

Gear Oil Type: 18 # Gear Oil

轧辊材质:Cr12数控加工 ;淬火处理硬度HRC58°-60°

Roll material: Cr12 numerical control processing; hardness of quenching treatment HRC58 - 60.

驱动电机:变频电机驱动

Driving motor: variable frequency motor drive

总电机功率:25kw

Total motor power: 25 kW

切断模具材质: Cr12MoV

Cutting Die Material: Cr12MoV

传动模式:齿轮箱

Drive mode: gearbox

切断方式:液压切断

Cut-off mode: hydraulic cut-off

切断尺寸公差:≤ ±0.5mm(长≤1000mm)

Cut-off dimension tolerance: <0.5mm (length <1000mm)

操作系统:触摸屏人机界面操控

Operating System: Man-machine Interface Control of Touch Screen

电气控制:三菱PLC程序控制

Electrical control: Mitsubishi PLC program control

占地空间: 20*2*3米(长×宽×高)

Coverage space: 20*2*3 m (length width height)

电器柜成型机,配电箱外框冲孔折弯一次成型设备“炜桦冷弯”我们更专业

Electrical cabinet forming machine, one-time forming equipment for punching and bending the outer frame of distribution box "cold bending of birch" we are more professional